Feeding speed | 13-23m/min |

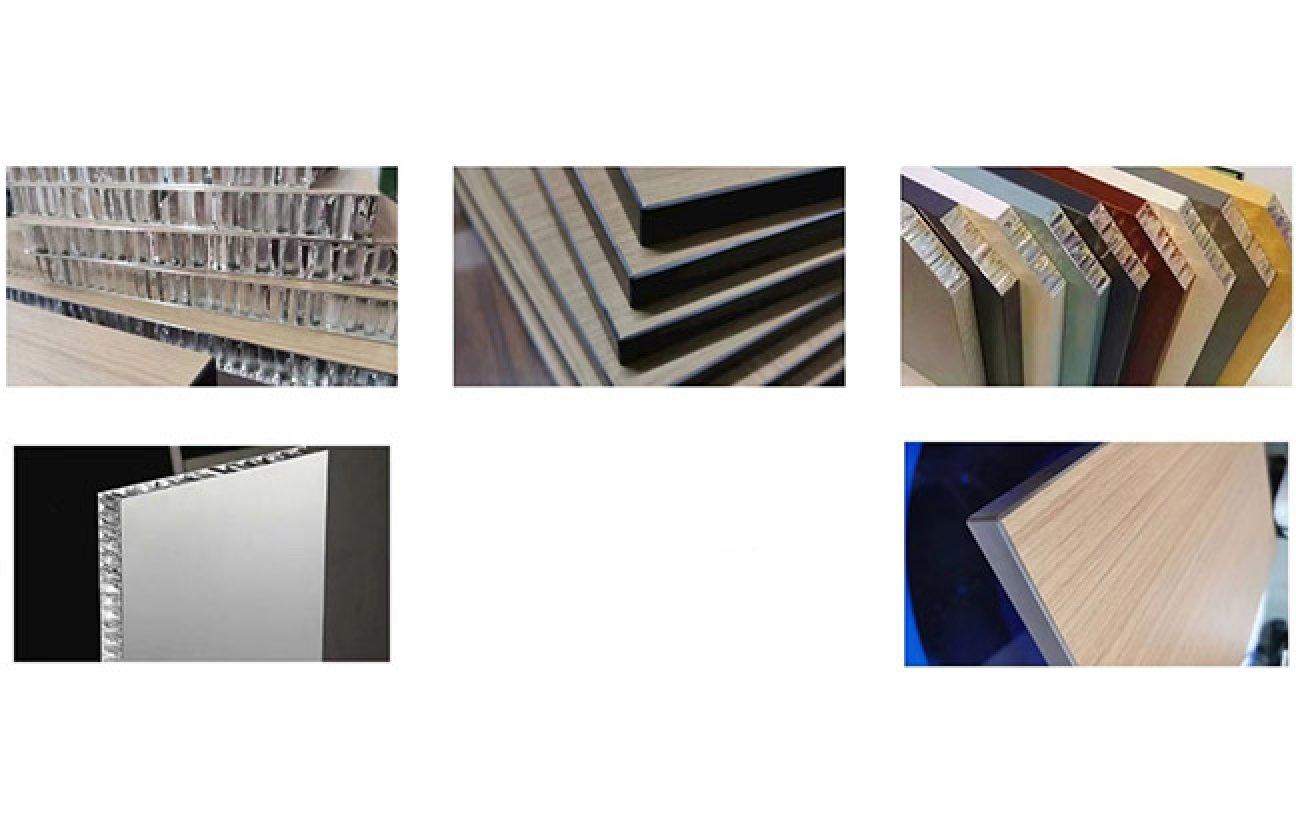

Panel thickness | 10-60mm |

Edge thickness | 1.0-3mm |

Panel width | ≥60mm |

Working pressure | 0.65Mpa |

Total power | 20kw |

Overall size | 8950*950*1850mm |

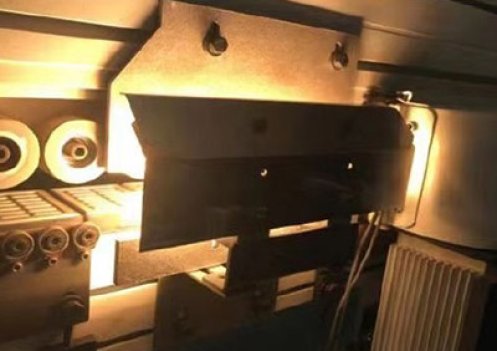

Scrape off the corrugation marks produced during the edge sealing process to ensure that the edge sealing and surrounding areas of the board are smooth and flat.

Flexible scraping will not damage the board, especially for uneven boards, glue can be removed, broken wires, etc., and replacement is simple and convenient.

Polish the edge-sealed boards, and use a cotton polishing wheel to clean the processed boards to make them cleaner and smoother after edge-sealing.

1. Mobile and portable body, automatic sol dispensing, convenient and practical, high efficiency. 2: PUR glue is waterproof, moisture-proof, good stickiness, anti-corrosion, high temperature resistance, material saving, and edge sealing effect.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

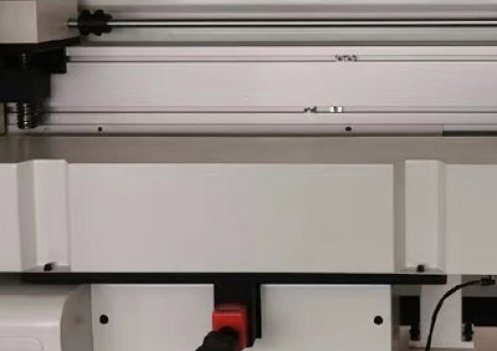

Belt pressing device, the movement of the belt is synchronized with the movement of the plate on the conveyor belt, and the edge of the plate is sealed through the pressing force of the surface of the belt on the side of the plate, and the edge band is strongly bonded.

Solve the problem of low adhesion of edge banding on workpieces processed by edge banding machines due to low factory space temperatures in winter. This device has plate heating and intermittent heating functions, which can effectively reduce energy consumption and production costs.

Re-modify uneven boards or corrugations, burrs or non-vertical phenomena caused by panel saws and cutting machines to make the board sealing surface smooth and allow the edge strips and boards to fit closely, thereby achieving better sealing edge effect.

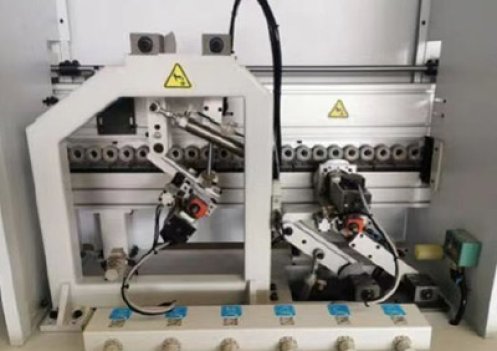

It is composed of a front flush head and a rear flush head. It uses automatic template tracking and high-speed motor to quickly cut the remaining material at the front and rear ends to ensure a flat and smooth cutting surface.

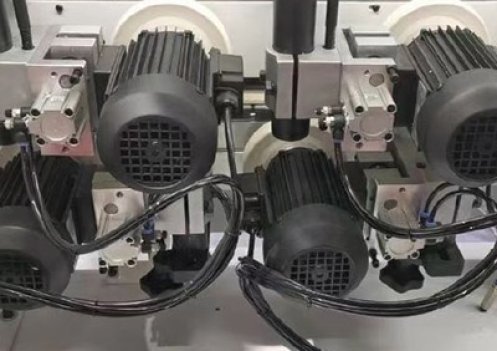

Carry out rough trimming and fine trimming of the sealed edge tape so that the upper and lower edges of the edge tape are flush with the upper and lower surfaces of the board. The desired curvature can be trimmed according to the needs, and the edge sealing effect will be better.

The corner trimming chamfering arc is even and smooth, which can make the end surface of the plate smoother and more beautiful, improving production efficiency and edge sealing effect.

It adopts a 6-pressure wheel structure to make the edge-banding tape adhere to the board surface more firmly. The high-precision large pressure wheel and the rubber coating wheel operate synchronously to ensure the pressing effect. The upper and lower push wheels ensure that the edge-banding tape adheres to the edge of the workpiece. The angle of the pressure wheel can be adjusted individually to reduce the glue line.