Model | MJ330C | MJ380C |

Sawing length | 3300mm | 3800mm |

Sawing thickness | 80mm | 80mm |

Dia. Of main saw blade | 355mm | 355mm |

Axis dia. of main saw blade | 60mm | 60mm |

Rotate speed of main saw blade | 3950/4500 rpm | 3950/4500 rpm |

Dia. of grooving saw blade | 180mm | 180mm |

Axis Dia. of grooving saw blade | 30mm | 30mm |

Rotate speed of grooving saw blade | 6300 rpm | 6300 rpm |

Saw carriage forward speed | 0-120 m/min | 0-120 m/min |

Saw carriage back speed | 0-120 m/min | 0-120 m/min |

Head saw motor | 15 kw | 15 kw |

Grooving saw motor | 2.2kw | 2.2kw |

Saw carriage drive motor | 1.5kw | 1.5kw |

Automatic feeding motor | 1kw | 1kw |

High pressure blower motor | 3kw | 3kw |

Automatic feeding speed | 0-40 m/min | 0-40 m/min |

Operation pressure | 5-7kg/cm | 5-7kg/cm |

Workbench height | 850mm | 850mm |

Net weight | 4000kg | 5300kg |

Dimensions(L*W*H) | 6100*6200*1700mm | 6450*6800*1900mm |

The Max cutting thickness is 80mm, 90mm is optional.

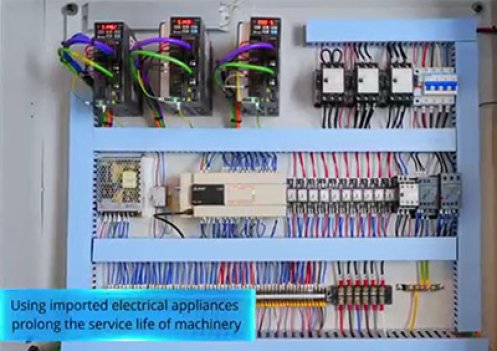

Japan Mitsubishi PLC control system.

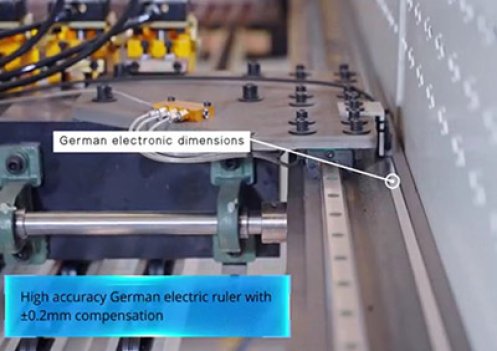

High accuracy German electric ruler with ±0.2mm compensation.

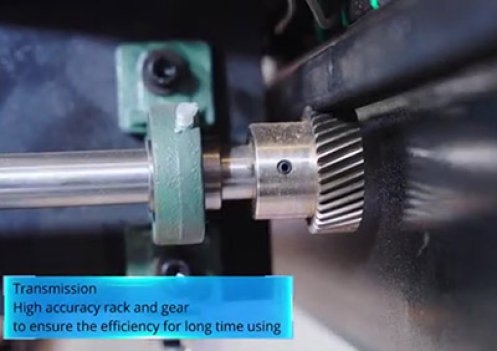

Transmission: High accuracy rack and gear to ensure the efficiency for long time using.

Multi pneumatic grippers are positioned by servo driver they are rubber coated will not scratch on the panels. All grippers grip and feed the panels automatically steadily with fast speed.

Cutting Optimization Software and Label Printer: Optimization software: Automatically generate the optimization sawing solution, can save personal calculation time and enhancing material utilization efficiency, which can save labor cost, material and enhance the efficiency. Label printer: one cutting board stick one label with all information on the label, such like customer name, board name, board thickness, width, length, easy for factory to control production.