-

Home>

-

Products>

-

CNC Router>

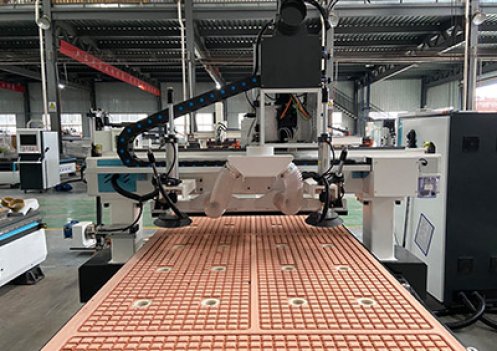

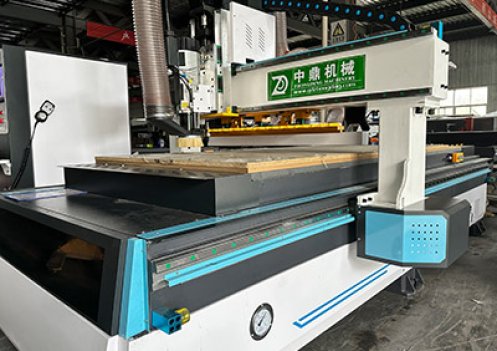

Model | ZD1325 – Atc cnc router with line tool magazine |

Working stroke | 1300*2500*200mm |

Running Speed | 120m/min |

Working Speed | 25m/min |

Device architecture | After sand blasting and stress relief annealing treatment, it is processed by CNC gantry CNC one-time forming and processing. The |

Spindle power | 9kW automatic tool changer spindle HQD |

Servo drive system | Three-axis 1.8kw high speed servo motor Z axis + brake |

Control System | Taiwan imported Syntec/WEIHONG processing center dedicated control system |

Speed reduction mechanism | Taiwan imported Wanxin reducer |

Rack and pinion | German imported brand ROR 1.5M high precision grinding helical rack |

Rail screw | Taiwan imported dragon horse rail + TBI screw |

Positioning way | 3+2 high-precision automatic positioning cylinder pedal-type one-key positioning device |

Bed structure | High-precision heavy-duty side-mounted bed, processed by large-scale CNC five-face milling center |

Countertop structure | Double-layer vacuum adsorption of 6 large partitions, multi-point adsorption / multi-slot design / adsorption uniform / instantaneous |

Electrical accessories | Japan imported OMRON relay, France Schneider relay alternate use |

Automatic tool calibrator.

Pushing device: simple and efficient, improve work efficiency.

9kw CC tool change spindle, suitable for efficient cutting, slotting, milling, milling and other processing of panel furniture.

Linear bearings, fluid & accurate: the 30mm linear bearing profile rails with stainless spring steel strip covers are standard in the X&Y&Z axis.

Double-layer PVC vacuum table design, Strong structure, no deformation, with instant adsorption and instant release functions.

Heavy-duty body welded by high-strength thick-walled steel pipes, annealing aging and sandblasting treatment, stable structure and guaranteed accuracy.