Banding tape thickness | 0.4-3 mm |

Banding tape width | 12-65 mm |

Work piece thickness | 10-60 mm |

Work piece length | >=100 mm |

Work piece width | >=50 mm |

Heating power | 1.8 KW |

Feeding motor power | 3.7 KW |

Pre-milling motor power | 2.2 KW x 2 |

Glue spreading power | 0.75 KW |

End trimming power | 0.5 KW x 2 |

Rough trimming motor power | 0.75 KW x 2 |

Fine trimming power | 0.75 KW x 2 |

Corner rounding motor power | 0.5 KW x 2 |

Polishing motor power | 0.37 KW x 2 |

Feeding speed | 10/16/23 m/min |

Air pressure | 0.8 Mpa |

Overall dimension | 6700x850x1520 mm |

Packing size | 6730x880x1580 mm |

N.W. | 2000 KGS |

G.W. | 2100 KGS |

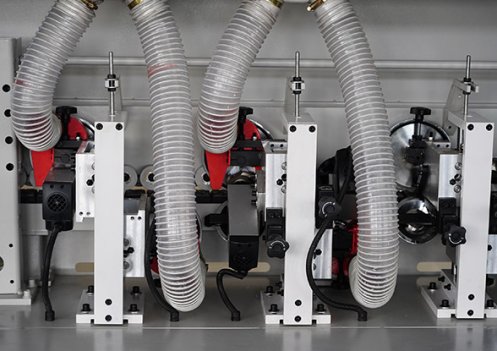

Pre-milling device uses double milling cutters to modify the ripple marks caused by the cutting board saw processing to achieve a better edge banding effect.

The glue pot is made of imported special ball bearing, high hardness and super wear-resistant material rubber box.

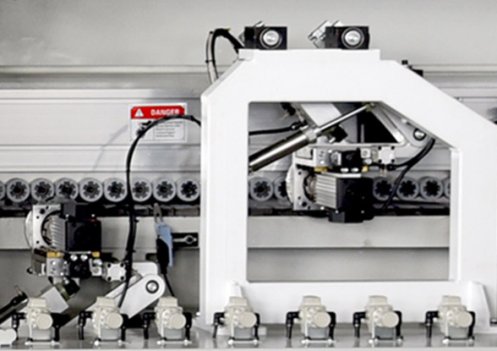

End trimming mechanism through a precise guide track movement, adopt automatic tracking and high frequency motor to ensure the cutting surface smoothly.

Rough and fine trimming adopts automatic roll forming structure and high frequency high speed motor etc. to trim and process excess edging material at the top and bottom of the sheet edge.

Corner rounding unit to round the 4 corners, is equipped with 2 HF motors, to get a smoother corner effect.

Upgraded scrapping mechanism with larger drive and large copy wheel to remove the wavy marks caused by the non-linear motion cutting process of trimming.