● 6side drilling machine is easy to operate

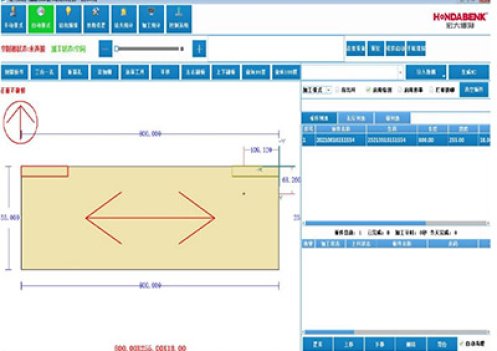

● Continuous scanning and automatic loading of machining graphics files

● History data memory function

● After the equipment is shut down and restarted, there is no need to return to the origin

● Long life service, stable and high precision

● Customizable, OEM &ODM

Main spindle | 2*3.5kw CC |

Spindle speed | 18000rpm |

Collect | ER25 |

Drive method | Servo-drive |

Drive motor | ESTUN absolute value servo |

Drive | ESTUN absolute value driver |

Frequency converter brand | EDT |

Frequency converter power | 3.7kw adjustable frequency converter |

Control system | Higerman system |

Reducer | Japan Shimpo |

Rail | Taiwan Square Rail |

Rack | German high-precision helical gear |

Positioning | Automatic positioning system |

Side leaning | Automatic |

Wire | High flexible cable |

Machine body | Heavy duty bed, annealed treatment |

Working table | Air floating tabletop, 0.75kw high pressure blower |

Dust collector | Up Φ200mm, down Φ125mm |

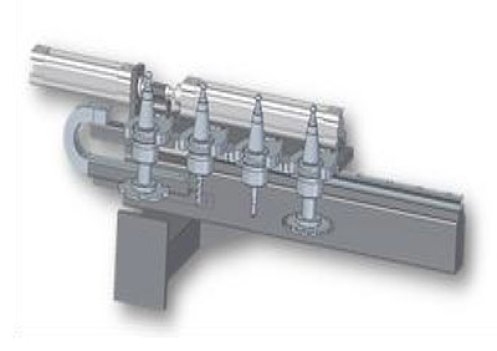

Four position linear tool magazine (Optional) Multiple cutting bits can be installed for various invisible parts processing and multi slot machining

Double grip, precise positioning

Six surface processing, one-shot complete

Continuous scanning: Supports barcode/QR code Scan and automatically load machining graphics files And automatically retrieve NC program processing

Independently adjusting tool processing speed: Tailored processing speed for each drill bit through processing data analysis, making production and processing more flexible

Flexible discharge (optional front/back/side discharge): Combined with automatic loading and unloading platform, multiple cutting options for convenient automation connection